TV's & Screens

A key item of e-waste are televisions and screens. Eco e-waste has the capacity to process nationally through its state operations based in each major capital city.

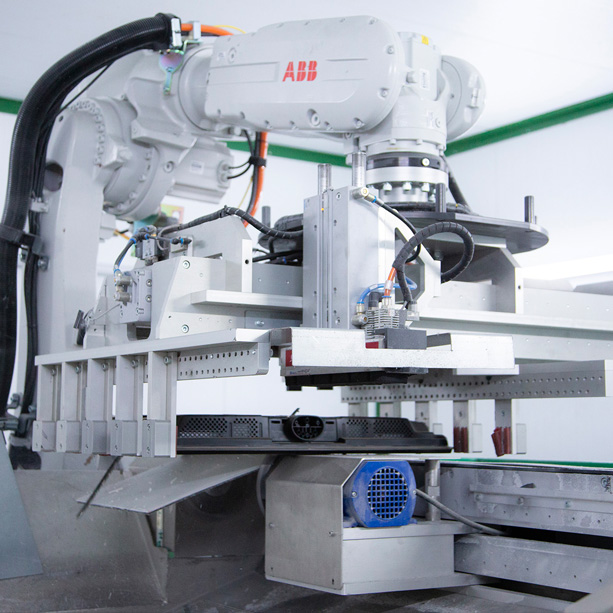

LED screens can run through any of our shredders, but with Flat screen models these are transferred to our Campbellfield facility where the mercury is removed. Here we process TV’s, monitors and laptops through our automated state of the art robotic equipment to ensure all the mercury is removed and recycled safely with out any harm or risk to our staff.

We recycle and process all types of televisions including, CRT/LCT/Plasma and LED.

A typical 40″ television contains around 60 feet of fluorescent tunes containing mercury which is highly toxic to human health. We also process monitors and laptops as these also have mercury within them.

We remove the fluoro tubes via a robotic process with the remaining material then being shredded. Once the steel is extracted from the processed e-waste at each location, the non-ferrous metals and plastics are sent to our specialist downstream sorting and separation plant in Launceston where we can extract the full range of non-ferrous metals separately. This sophisticated separation plant sorts out the grades of aluminium, 316 from 304 stainless steel, zinc, printed circuit boards, copper, brass, etc. It removes all metal down to 1mm in size and recovers all the gold and precious metals which are sent for refining. It is the most advanced and futuristic separation plant in the Southern Hemisphere. Additionally, the plastic will also be recycled in Tasmania and sorted into their various grades.